SSI Shredding Systems

Who We Are

Since our inception in 1980, SSI Shredding Systems has established itself as an engineering design company that builds what it creates.

We are a group of highly experienced and dedicated application specialists, engineers, designers and technicians. We seek to provide continuous value: from the initial opportunity to project installation, and throughout the life of the product. At SSI we say: “The best part of the relationship begins with product delivery”.

Over 35 Years of Solutions

SSI Shredding Systems, Inc. was formed in January 1980 in Wilsonville, Oregon when the idea of mobile shredders was new. The company’s initial product offering was a self-contained mobile shredder used to provide contract shredding services to industrial and government organizations. Use of this service was instrumental in developing the military’s widespread use of mobile shredding.

SSI Shredding Systems, Inc. was formed in January 1980 in Wilsonville, Oregon when the idea of mobile shredders was new. The company’s initial product offering was a self-contained mobile shredder used to provide contract shredding services to industrial and government organizations. Use of this service was instrumental in developing the military’s widespread use of mobile shredding.

Flexibility was key in SSI's early development. Our customers frequently came to us with unique problems, which compelled us to concentrate on engineering new solutions rather than off-the-shelf technology. The old idea that there was one solution for all, just wouldn't work in this market. Our customers needed a choice of options.

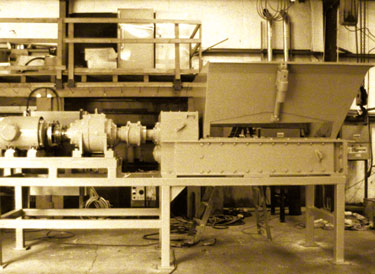

As the processing needs of SSI's customers grew, the demand for shear shredders expanded from temporary use to a need for dedicated systems. To address customers’ changing requirements, SSI began engineering and manufacturing a full line of rotary shear shredding systems. The manufacturing experience as well as the operations and service expertise gained in the mobile shredding business positioned SSI to effectively meet customer needs and develop new market opportunities.

A Global Approach

In 1988, SSI focused its expansion efforts on the Pacific Rim and has since provided several hundred installations in Japan alone. Our customer solutions continue to expand around the globe. SSI has shredding machinery and integrated systems installed spanning all 7 continents and in many countries. Some of our experiences include:

- Processing solid waste in Antarctica

- Medical waste in Africa

- Copper recycling in Brazil

- Waste-to-Energy in Costa Rica

- Pulp & Paper processing in China

- Metal recycling in Turkey

- Tire recycling across North America and Western Europe

Today, SSI has become a worldwide industry leader in the design and manufacture of one-, two-, three-, and four-shaft shredders, primary reducers and high density compaction systems to meet the diverse needs of industrial, municipal, and hazardous environments.

Why Shredding?

Technological advancements combined with depleting supplies of natural resources have made it now less expensive to reclaim useful materials from used products than to harvest raw materials from the earth.

Items such as used water and soda bottles can be converted into textiles and carpet. Old, worn out car tires can be converted into mats, sports surfacing and roadways. Obsolete electronics and children’s toys can be shredded, processed in an automated recovery system, and converted into materials that are used to make similar products over and over again.

SSI recognizes that its continued contribution to a sound environment lies not only in recycling and waste treatment, but in helping industry maximize production efficiencies and minimize scrap and waste by-products. SSI is committed to the ongoing development of size reduction solutions for industry as it responds to the dynamics of global environmental, regulatory and economic demands.

Shredding is more than just a way to downsize waste for disposal. It is the first step in almost any recycling or material reclamation process. It is one way to help sustain our planet and way of life.

SSI At A Glance

- Leading worldwide supplier of size reduction technology:

- Shredders (1, 2, 3, and 4 shaft designs)

- Primary Reducers

- Pre-Load Compactors

- Standard and Custom Products

- Integrated Systems

- Well established Asian presence

- Average installation size 200HP/149kw

- Multiple manufacturing facilities located in Wilsonville, Oregon USA

- Complete in-house manufacturing capabilities

- On-site demonstration testing to permit first-hand solution validation

- Comprehensive parts & service to support long-term customer success