PAPER: Loose Paper (SR400)

Watch Video

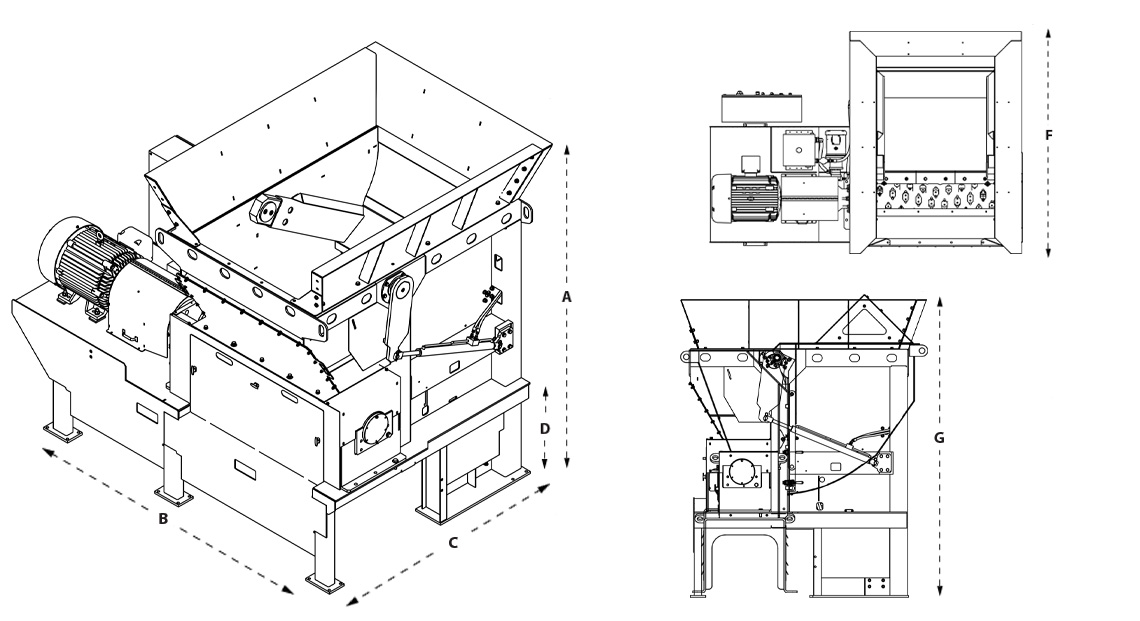

Shredder Model: |

Uni-Shear® SR400 |

|---|---|

| Cutting Chamber (WxL) | 1,320 x 1,320 mm (52 x 52 in) |

| Machine Length (B) | 5,548 mm (18' 2") |

| Machine Width (C&E) | 2,806 mm (9' 2") |

| Machine Height (A&G) | 2,656 mm (8' 8") |

| Discharge Height (D) | 578 mm (1' 8") |

| Hopper Width (F) | 2666 mm (8' 10") |

Shredder Model: |

Uni-Shear® SR400 |

|---|---|

| Drive | In-line direct-drive |

| Power | 75 kW (100 hp) |

| Voltage | 460/3/60 standard; other options available |

| Number of Cutters | 54 |

| Rotor Diameter | 400 mm (16 in) |

| Rotor Speed (rpm) | 110 |

| Screen Sizes | 12-150 mm (½-6 in) |

| Active Rotor Length | 1230 mm (52 in) |

| Cutting Chamber (WxL) | 1,320 x 1,320 mm (52 x 52 in) |

| Hopper Capacity | Approx. 2 m3 (2.6 yd3) |

| Machine Length | 5,548 mm (18' 2") |

| Machine Width | 2,806 mm (9' 2") |

| Machine Height | 2,656 mm (8' 8") |

| Machine Weight (less HPU) | Approx. 6,577 kg (14,000 lbs) |

| Hydraulic Ram | 1 kW (2 hp) |

Consult factory for other models and to discuss your processing requirements.

Note: Illustrations, specifications and descriptions presented reflect standard product at time of publication and are subject to change without notice. Dimensions are approximate. Photographs may include optional equipment and accessories. SSI offers compactors, balers, granulators, conveyors and classifiers as well as specialized motors, stands, hoppers, and mobile configurations.